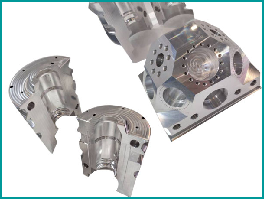

The innovation of CNC machined aluminum has brought CNC components and components that manual in a huge scope of administrations (Turning, processing and crushing). Today, very many machined CNC aluminum components are filling in prominence withinside the designing vicinity via DDPROTOTYPE .

Coming up subsequent are a part of the CNC machined aluminum components:

- Front boards

- Dowels Pins

- EMI-Housings

- Spline Shafts

- Clinical Devices

- Lighting Fixtures

Step through step commands to live far from distortion

Aluminum is considered the predominant cutting-edge fabric, however, it has a considerable fixing. The mixtures include fairly little solidity and the heat extension is excessive, can distort whilst being machined right into a slender part. Notwithstanding, some degrees may be occupied to shun the twisting of the fabric in advance of time.

Balanced Machining

It’s essential to avoid an outrageous grouping of hotness however as an alternative to make a scattering of hotness to reduce the tempo of heat distortion.

Defined Multiple Machining

On the off danger which you have some depressions on a few aluminum mixture plates, you may without lots of a stretch curve one hollow divider gave the electricity dispersion.

Get an Appropriate Cutting Parameter

The important effect at the slicing boundary is the degree of scaling lower back profundity. To preserve up with talent and decrease the amount of slicing. A CNC processing can settle the trouble, by rushing up the device and lessening the slicing electricity.

Penetrating and Milling

At the factor whilst the processing, the shaper is implemented to melancholy and components, the slicing is adequate. The activates reduce hotness, extension, and distortion. The maximum perfect manner of maintaining far from this trouble is pre-uninteresting with a more tool than the processing shaper and afterward, placed the processing shaper and factory.

Axis CNC Machining

On the five-hub machining, the CNC movements at the same time as slicing in 5 factors of the tomahawks at the identical time. This machining machine is quick, reliable in making plans complicated components, as paintings are drawn nearer in diverse ways.

The five-hub machining has been taken on usually because of the accompanying:

The set-up is a solitary one, and this lessens the lead time and higher the effectiveness. It allows higher calculation due to its ability to avoid the crash with the tool holder moving the desk or the slicing apparatus.

Can make use of greater constrained apparatuses which are greater inflexible, a few with excessive shaft speeds charge that is executed through diminishing the heap slicing tool. Pieces don’t undergo diverse workstations as a result errors are decreased, precision is saved up with, and pleasantness is ensured.

As we close, you’re currently conscious of the exclusive CNC machined aluminum processes (processing, uninteresting, and turning) that an incomplete piece of aluminum is taken via till it becomes a complete object. It’s a tough interplay that calls for insight, precision, and first-rate hardware. Besides, those are a right away result of the various aluminum composite utilized.

The blessings of aluminum are self-evident: excellent slicing interplay, the excellent pleasant, and the hobby for a machined aluminum object are at the ascent. Businesses are collecting momentum with several specialists to cope with your issues, make certain to do your exam, and search for exams to make sure of the character of the CNC aluminum.