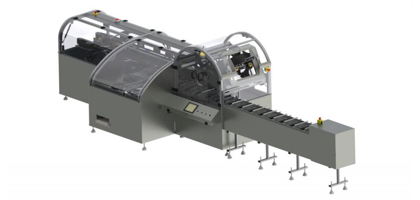

Automatic cartoning machines can help with soap cartons, tube cartons, bottle cartons, bottle cartons, inhaler packaging, bearing cases and more. Automatic Cartoning Machine is suitable for handling many items such as tubes, blisters, vials, vials, ampoules, droppers, inhalers, film rolls, bearings, soap and many different items that fall into a wide range. Part of the Cartoner Machine individually or mixed. Cartoning machines have built-in elements for product inspection, carton retrieval, code embellishment, carton blade erection, folding package retrieval, product loading, carton sealing, and carton unloading. Continuous operation of the cartoning machine with a result of 120 to 240 cartons per minute.

We use a cartoning machine to produce various types of containers. It is also known as “cardboard”. This modern hardware covers and fills boxes and other packaging bins. Even though some cartoning machines require the input of human labour, most of their parts are programmed. This is a claim that a cartoning machine is considered a necessary piece when assembling a sequential building system. Cartoning machines are available in various shapes and sizes. First of all, the cardboard sheets are inserted into the machine. Once the boards are set up, the machine starts crushing them into different types of boxes. The next step is to stack these boxes with different items. After this development, the machine closes the folds of the bushings by adding cement or paste.

Different types of cartoning machines

In today’s work environment, 3 types of cartons are commonly used. Here is an overview:

- Horizontal Carton: This carton is well known for handling bulk items and achieving high rates for attractive applications. This is a statement that it is the most recognized board used in the binding industry for finishing. It is an optimistic decision to keep things consistent and to keep a few things in mind. It can be divided into three sub-classifications:

- Fully automatic (for best productivity and packaging)

- Self-loader (for increased productivity and better control)

- Download the manual (for cost adjustment and adjustment)

- Vertical Cartonnage: This carton is a unique choice when it comes to handling bowls, containers and jugs. Damage to the object during gambling is minimal when working with it because this carton occupies long frames when serving. The administrator, therefore, has the opportunity to reduce cycles and impressions. It can be divided into four sub-classifications:

- Coordinated Delta 3 systems (for high and accurate PPM)

- Continuous motion tower loaders (for speeds over 200 PPM)

- Top Load with irregular movement (for high accuracy and adaptability)

- Manual (for reasons of economy)

- Slippers: This is best for things like pockets and rankles packs. This carton is especially adept at providing folding sleeves. This board uses a small amount of inner material and lining. However, the arrangement of this carton is not very reliable. It can be divided into three sub-classifications:

- Fully automatic (for best skills and packaging)

- Self-charging (for more advanced skills and more noticeable control)

- Manual (for adjustment and corresponding costs)

Conclusion:

Cartoning and cartoning machines help organizations meet production goals because they are fast and productive when it comes to performing many tasks. After a few hours, they also have to adjust and reduce costs. Anton Donald is a mechanical specialist working in an organization that manufactures dust cutting machines. He is also an avid blogger. This article will discuss the different types of cardboard machines such as cardboard.