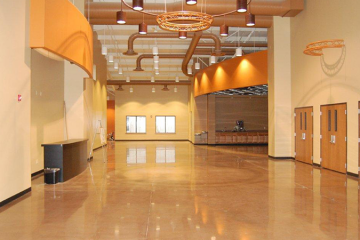

Concrete polishing is the ideal finish for most owners of new and current concrete surfaces. The process is easy to implement with state-of-the-art technologies. Low cost, reliability and limited upkeep make this the perfect form of flooring for retail, commercial and other high-traffic circumstances. Yet what precisely is the polishing of diamond concrete with carr restoration ltd ?

- What is a Diamond Stone Polishing?

The method of diamond concrete polishing is fairly straightforward. The abrasion pads file off the top sheet of the concrete. First, the diamond-embroidered abrasive pads buff and polish the surface until it shines. The polished coating is then coated to preserve the look and increase the longevity of the cement.

- Ideas in architecture.

Color Diamond concrete floor polishing gives customers a range of choices for improving the look of their walls. Customers can order shaking-on or penetrating chemical stains and dyes to change their gray concrete to any number of colors, to improve the color of the surface.

Project Dying is not the only design choice for polished concrete floors. In addition to the mirror-like shine, concrete flooring can be embossed with patterns, curves, pictures, grids and other designs. They are inserted in the floor with a saw, so the construction possibilities are adjustable.

In conjunction with or as an alternate decoration or pattern, aggregates or other objects such as coins, nails and colored glass may be incorporated in the concrete. The coating is then polished to a smooth, clean, high-gloss finish.

- Will all of the concrete be brushed.

Polishing can be added to the noisiest concrete floors. Once they have been repaired, new concrete structures are brought to light easily and cheaply.

Older concrete profits greatly from the polishing of diamond material. In high-traffic areas, the gloss spruces up and evens out wear spots. Older floors may need extra cleaning, patching or repairs before they can be cleaned. But in many situations, it saves thousands by allowing customers to reclaim their old floors instead of tearing them down and starting anew.

- Is that slick.

Polished concrete flooring looks a lot slicker than it is. The surface applied to coated flooring is glossy but is thoroughly tested for slip protection at all traffic levels.

- Polishing Equipment-The way it operates.

Concrete is polished with a diamond disk grinder or a walk-behind grinder. The grinder spins diamond-impregnated disks with a mix of grits. The grinders begin with rough grits and switch to fine grits until the concrete is neatly polished. Since the polishing process takes place layer by layer, consumers can pick the amount of gloss they like on their concrete floors.

Concrete floors can be wet or dry painted. Customers tend to have different tastes. Wet polishing produces excess slurry that quickly extends to hard-to-find places that are hard to reach. This is called hazardous waste in most countries and must be disposed of by law.

Dry grinding produces a large amount of dust. Professional contractors monitor the dust using a high-performance vacuum system. This effectively removes airborne particles when applied correctly.